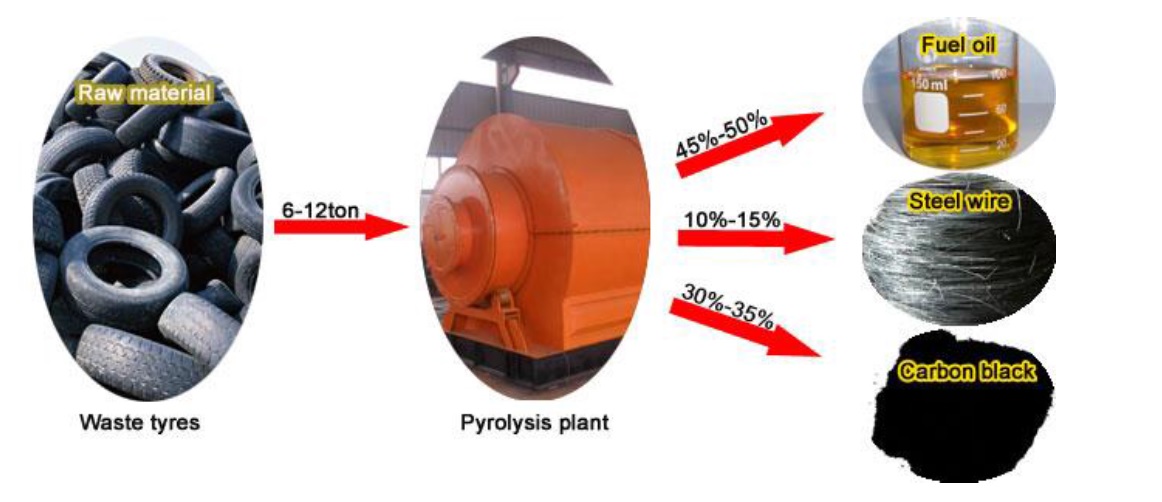

Manufacturing Process

- Feed the waste Tyre into reactor and seal the feeding inlet door tightly and make sure is no gas leakage.

- Heat the reactor by using coal, charcoal, fuel gas, wood , fuel oil etc.

- The reactor will be slowly heated and when the temperature reach about 250°c the oil gas will formed.

- The oil gas coming out from the reactor then goes to condensing system and become liquid oil.

- The gas which can not liquified under normal pressure will be designed to go back to combustion system through safety device.

- It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

- After finishing oil production, the temperature of pyrolysis reactor will fall down, When the temperature fall down to 40°c, we can get carbon black and steel wire.

Product Details

At present, we manufacture Three grades of TPO :- Light Oil : Density (0.91-0.92 g/cc)

- Heavy Oil : Density (0.93-0.95 g/cc)

- Mixed Chemical Oil : Density (0.88-0.89 g/cc)

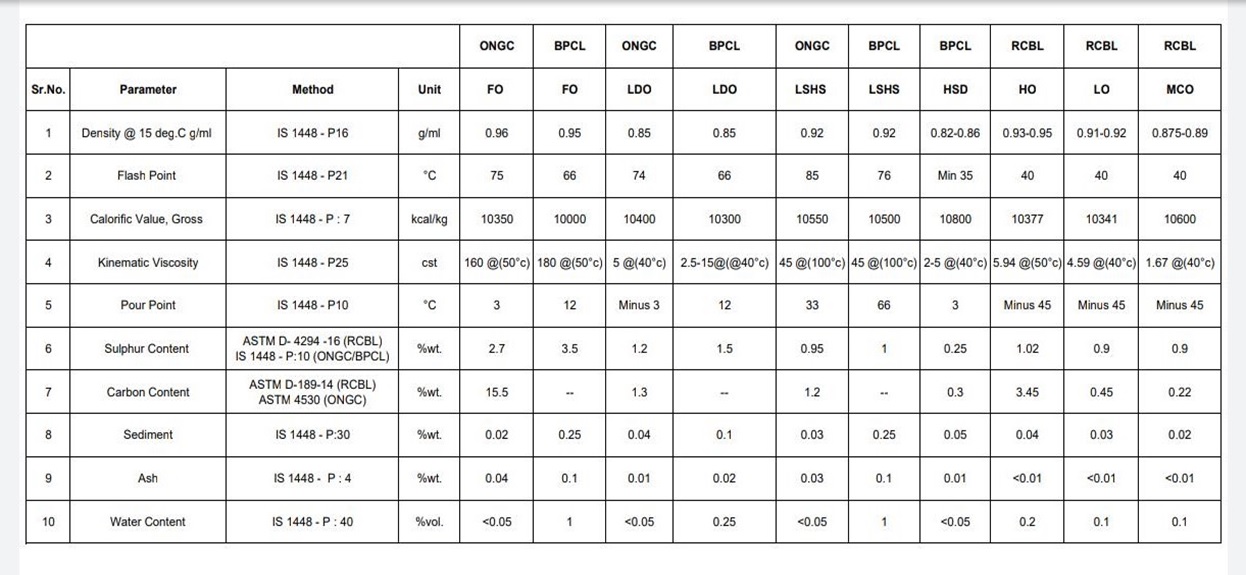

- We recommend you to replace your LDO with our MCO and Furnace oil with our Heavy oil.

- It is a 100 % replacement of LDO and Furnace Oil

Advantages Of Pyrolysis Oil

- No Need Of Preheating

- Low Sulphur Content

- Low Carbon Content

- Density and Viscosity Is Less

- High Calorific Value

Comparison Chart

Application Of TPO

- Use as Fuel : The use of TPO as a substitute to fuel is an opportunity in minimizing the operational cost and minimizing the utilization of the natural resources.

- Distilled fraction blend with other fuel oil.

Handling and Storage

- Stability : Material is stable under normal storage and handling situation

- Incompatibility : Avoid contact with acids and oxidizing agents.

- Storage : Store in tight sealed container at ambient temperature in well ventilated areas. Do not store near flame or heat.

- Handling : Only in well ventilated areas. Keep container closed when not dispensing product. Avoid body contact. Use grounding and bonding devices when transferring material.

First Aid Measures

- Eyes : Flush with eyes solution or large amount of water.

- Skin : Immediately wash with warm water and soap.

- Inhalation : Remove to fresh air. Get medical attention if symptoms occurs.

- Remove contaminated clothing and Wash contaminated clothing before reuse

Accidental Release Measures

- Small Spill Control and Recovery :

Oil absorbent should be used to contain and soak up oil. Do not use a combustible material. Wear appropriate personal protective equipment - Large Spill Control and Recovery : Safely eliminate the source of the leak. Eliminate ignition sources. Prevent runoff from entering Storm sewers and ditches. Water fog can be used to control vapours